What Does a Desiccant Use and Maintain Dry Environments?

Desiccants are used to create and maintain dry environments by absorbing moisture molecules. They have many applications and industries they can be found in, including:

Retaining food products, like jerky, at their peak freshness. Preventing corrosion in metal materials used in electronics and machinery.

Desiccants are found in small silica gel packets inside some medicines to inhibit mold growth and keep their potency potency at maximum potential. Reusable provide an eco-friendly moisture control solution.

Safety Considerations When Using Desiccants

Desiccants are non-toxic and safe to handle, making them an economical solution to moisture control. Furthermore, their environmental footprint is minimal – many options such as clay or activated charcoal break down naturally over time and reduce waste. They’re even safe for food packaging applications; providing they do not come into direct contact with food products – clear labelling helps avoid accidental ingestion as does use of sachets or canisters that isolate the from food products to lower risk.

Desiccants should always be handled with great caution and kept out of reach from children or animals, particularly silica gel packets which could potentially be mistakenly consumed as food by curious youngsters or pets. To reduce this risk, all desiccants must be clearly labeled and stored in food-grade packaging to reduce risks to young ones and pets alike.

Desiccants can be useful tools in the fight against food waste. While are effective for preserving dry goods, they should not be used with products requiring moisture such as cheeses which require specific humidity levels to stay soft and delicious; could thwart this by drying out and hardening foods, preventing them from attaining their intended texture and taste.

Medication and pharmaceuticals can be damaged by excessive moisture, rendering them less potent or expiring prior to their intended date of use. Silica gel packs offer an ideal storage solution for safeguarding these items against moisture damage while maintaining their effectiveness.

Precautions to Take When Handling Desiccants

Desiccants can be valuable tools in protecting metal parts during storage and shipping from issues like rusting and corrosion; however, when used improperly they may pose health concerns.

Desiccant manufacturers must adhere to stringent food safety standards when producing for dry-absorbing applications, which prevent them from contaminating packaged food or medications. This is particularly important in regards to bags enclosed within food-grade packaging.

Desiccant bags must also be tailored to their environment of storage or transportation. For instance, bags that will be sent into an environment with high humidity levels should utilise molecular sieves instead of silica gel in order to prevent premature saturation.

Size-appropriate packs must also be selected for placement within their intended packaging volumes in order to minimize how much material will be lost during shipping and storage processes.

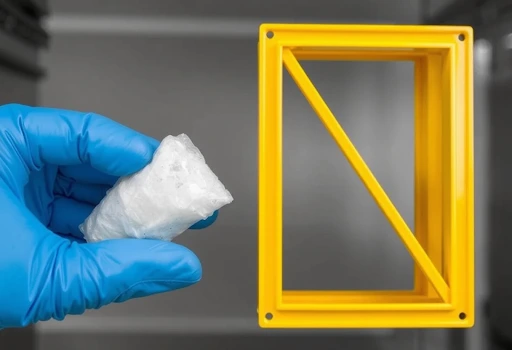

Last but not least, it is essential to remember that loose powdery packs like silica gel can produce dust when being handled, which may irritate respiratory tracts when inhaled. Therefore, must only be handled in well-ventilated environments or if necessary wearing protective masks to minimize exposure – this will also minimize risks of damage or contamination to other materials coming in contact with these packs.

Desiccant Safety Data Sheets (SDS)

primewires sections 1-8 provide general information about a chemical. This includes safety precautions, hazard ratings, storage requirements, and emergency response information. sections 9-16 contain additional technical and scientific details regarding that particular chemical, such as physical properties, toxicological details, and exposure control measures.

A Safety Data Sheet should list all ingredients and chemical names. Furthermore, Section 4 (Chemical Stability and Reactivity) must include information on how chemicals interact with other substances as well as potential dangerous reactions that could take place – this includes classes of incompatible materials that might interact in ways to produce dangerous conditions.

Section 8 (Exposure Controls/Personal Protection) includes recommendations on engineering controls to reduce exposure, as well as details of personal protective equipment needed when working with chemicals, and provides recommendations regarding appropriate types of eye, face, skin or respiratory protection depending on hazard or potential exposure levels.

Desiccant Packaging

Desiccants provide protection from moisture damage during transport, storage and use. Unlike traditional packaging materials, utilize hygroscopic materials that absorb any vapor generated within their enclosed environments in order to keep things dry and maintain dry environments.

Silica gel is one of the most widely-used , thanks to its interconnected pore structure which creates an abundant surface area that absorbs up to 40% of its weight in moisture. Packaged into small sachets for ease of use at lower temperatures, silica gel has proven itself as an extremely reliable way of controlling humidity levels and helping avoid spoilage, mold growth, or product degradation due to increased humidity levels.

Musical instruments represent a considerable investment, so it is critical that they remain safe from excess moisture. Desiccant packets can help absorb any extra humidity that might otherwise lead to rust or mold growth in instrument cases or storage cabinets, providing added protection from mold growth and corrosion.

Moisture damage to classic cars in storage can be disastrous, wreaking havoc with interiors and molding exteriors alike. Desiccant packs can help absorb humidity levels to preserve and protect this important vehicle for years to come.

AGM’s desiccant calculator enables users to determine how many desiccant packets are needed based on an internal volume measurement, and displays unit quantity amounts for silica gel, molecular sieve and clay desiccants. Our pharmaceutical-grade desiccant sachet production processes adhere to GMP and ISO standards and include FMEA processes with single batch delivery as well as automated quality controls with documented change controls for added peace of mind.

Read also:The Uses of Desiccant